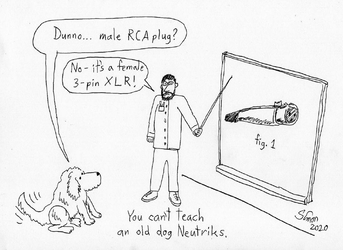

Problems identifying connectors

- Thread starter sawdust123

- Start date

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

- Status

- Not open for further replies.

Things have gotten a little better in the DJ realm.

In the 1980's all retail DJ gear came with RCA input and output, 1/4" unbalanced mic inputs, it was consistent with home stereo equipment. Only some of the lesser known professional installation brands like Biamp, Meteor, Rane, and GLi had truly balanced input or output. Even worse, unbalanced (1/4) legacy microphones (U.S. versus Europe) did not have a consisent wiring standard, and if you didn't know when using mixed brands - one would would assume you suddenly had a bad mic or bad cable, even though it just worked somewhere else. Early numark mixers with XLR outputs were only "pseudo-balanced" and prone to noise.

Today, I think most DJs know XLR is the better choice even if they don't understand why. Many may also know the difference between TRS vs TS on a 1/4 plug or jack. This latter one though still confounds the general public and some DJs. If I had a dime for every problem I've resolved at a shcool, church. or other installed system simply by disposing or their 3.5mm TRS to XLR cable I'd be rich. I think DJs may sill be on the learning curve with certain twist-lock (Speakon) connectors, i.e. that you can feed a NL4 from an NL2 but not the other way around, and then why an NL4 or NL8 even exists.

The problem is compounded by Chinese manufacturers who for a long time online would sell you anything you could possibly conceive. I could previously surf Amazon.com and find unique cable products such as:

Just straight through wires - not a converter, extractor, or isolator, of any kind. While any individual person could use any connector for some unique purpose - that doesn't explain why manufacturing facilities saw fit to produce an inventory of non-sense never in the real work cables to sell online. It also makes me wonder how many of these actually sold to uninformed consumers worldwide?

In the 1980's all retail DJ gear came with RCA input and output, 1/4" unbalanced mic inputs, it was consistent with home stereo equipment. Only some of the lesser known professional installation brands like Biamp, Meteor, Rane, and GLi had truly balanced input or output. Even worse, unbalanced (1/4) legacy microphones (U.S. versus Europe) did not have a consisent wiring standard, and if you didn't know when using mixed brands - one would would assume you suddenly had a bad mic or bad cable, even though it just worked somewhere else. Early numark mixers with XLR outputs were only "pseudo-balanced" and prone to noise.

Today, I think most DJs know XLR is the better choice even if they don't understand why. Many may also know the difference between TRS vs TS on a 1/4 plug or jack. This latter one though still confounds the general public and some DJs. If I had a dime for every problem I've resolved at a shcool, church. or other installed system simply by disposing or their 3.5mm TRS to XLR cable I'd be rich. I think DJs may sill be on the learning curve with certain twist-lock (Speakon) connectors, i.e. that you can feed a NL4 from an NL2 but not the other way around, and then why an NL4 or NL8 even exists.

The problem is compounded by Chinese manufacturers who for a long time online would sell you anything you could possibly conceive. I could previously surf Amazon.com and find unique cable products such as:

- USB to XLR

- HDMI to RCA

- 5 Pin DMX Y-cable

- VGA to HDMI

Last edited:

There was a company about 20 years ago that was selling standard AC plug/receptacle (NEMA 5-15P/R) adapters to XLR. I think they also made IEC (C13/C14) versions too. The idea was that if you ran out of XLR cord, you could use a standard extension cord. The company was called J-CON which stood for Jesus Christ of Nazareth. I think they named it such because if you used their adapters, there was a good chance that you would be meeting Jesus soon. They apparently tried to exhibit at AES one year and got kicked out.

I can imagine finding that kind of improvised connection in an old church where resources were short and people used whatever materials/wire they had on hand , but I highly doubt that product is a true story. Perhaps it was a different kind of Tx/Rx product but lacked UL and other approval.

There are (or have been) products that can transmit audio over existing AC cabling but there is no actual connection between the audio and AC wire. It's a Tx/Rx system - a transmission that piggy-backs on the same wires and is received at the other end by a companion device.

I imagine they would also work the same across a live extension cord, but I think the only useful applcation for that would be sending and audio signal from a clubhouse to an outdoor tent where an AC line making that run is already safely in place.

Wireless networking and Cat5 have largely made these products obsolete.

There are (or have been) products that can transmit audio over existing AC cabling but there is no actual connection between the audio and AC wire. It's a Tx/Rx system - a transmission that piggy-backs on the same wires and is received at the other end by a companion device.

I imagine they would also work the same across a live extension cord, but I think the only useful applcation for that would be sending and audio signal from a clubhouse to an outdoor tent where an AC line making that run is already safely in place.

Wireless networking and Cat5 have largely made these products obsolete.

Last edited:

I saw the product at NAMM one year. They were in Hall E (basement) where the cheap off-shore knock-offs and start-ups used to exhibit. I spoke to the guy in the booth and it definitely did NOT have UL approval. I was telling friends about the stupidest product I had seen that year and one was the guy that kicked them out of the AES show (he was a past AES president and spent over a decade on the board of governors).I can imagine finding that kind of improvised connection in an old church where resources were short and people used whatever materials/wire they had on hand , but I highly doubt that product is a true story. Perhaps it was a different kind of Tx/Rx product but lacked UL and other approval.

BTW, the Ebtech HumX also lacks UL approval and it has been selling for well over 10 years. It works by placing parallel diodes in opposite polarity on the ground leg. UL does not allow components on a ground leg. The diodes block ground loop currents below 0.6 volts. The diodes are rated at only 6 or 10 amps if I recall correctly. However, ground faults can easily exceed 25 amps and blow those diodes. If the diodes fail in an open circuit condition before the breaker pops, you lose all safety protections and have a potentially life-threatening situation. Granted, diodes more frequently fail in a shorted condition but would you risk your life on that?

You're wrong about that. I have my own custom loop installed on ALL of my quad boxes and power strips. Diode failure simply means they lose their ability to block the low level ground loop. The circuit itself does not open and a safety ground remains intact. 10A is not a destructive material limit - it's the point at which the desired property of the diodes circuit permanently lost. (For example, anyone who uses a Hum-X and STILL ends up with a ground loop owing to the AC lines is using one that has been subject to an overload and no longer works properly.)BTW, the Ebtech HumX also lacks UL approval and it has been selling for well over 10 years. It works by placing parallel diodes in opposite polarity on the ground leg. UL does not allow components on a ground leg. The diodes block ground loop currents below 0.6 volts. The diodes are rated at only 6 or 10 amps if I recall correctly. However, ground faults can easily exceed 25 amps and blow those diodes. If the diodes fail in an open circuit condition before the breaker pops, you lose all safety protections and have a potentially life-threatening situation. Granted, diodes more frequently fail in a shorted condition but would you risk your life on that?

25 amps is also not a ground fault - it's a dead short. I know because I've tested my own loops in dead short conditions on live wires and under sustained loads exceeding 20A. They don't break the ground connection and they don't even get warm. The combined core conductors provide the same wire gauge as the grounding conductor. 10A diodes in an opposing pair (20A path) will each loose their directional properties as the current approaches 10A but it won't break the circuit. (There's also a small resistor in that circuit that balances the paths.)

Since adding this component to my electrics I have not experienced a ground loop at anytime in any venue - including venues that had previously presnted consistent groud loop issues with audio systems. I've also experienced far less static electricity as well around stage fabrics and material in proximity to our cabling. I attribute that (with no atual proof) to less ground variation interactiion between my power strips/boxes and thh materials they are in contact with.

A 15 amp rating makes sense if Hum-X is selling these loops as a insertablde product because a 20A circuit breaker on average will trip within minutes at a sustained load of just 16A. The rating leaves substantial headroom and the edison plug all but guarantees these things will never be comnnected to a source that exceeds it's gorunding capacity.

UL labs is not an authority and their listngs have no regulatory role. UL approval simply acknowledges comformity to existsing manufacturing methods commonly used in the USA. Other countroies have similar agencies benefitting their own domestic production methods. It's useful in commerce, but lots of people are still injured or life threatend by "listed" products all around the world.

Last edited:

Bob, the only thing I think you can take issue with is my use of the word ground fault. Many are familiar with GFI (ground fault interrupter) devices which react to small current differences between the Line and Neutral conductors of a branch circuit. Such faults are often caused by higher than normal leakage currents that find a path to ground other than the neutral conductor. A 10 mA leakage current is sufficient to trip a GFI breaker. I used to the ground fault term to mean ANY improper grounding situation including short circuits.

As you are probably aware, circuit breakers can have thermal and magnetic trip modes. Thermal breakers take time to warm up and trip. How much time depends on the current level and ambient temperature. Thermal breakers are good at dealing with high in-rush current loads as they won't trip over the short duration of the in-rush. Their slow response makes them less prone to nuisance trips. Magnetic tripping is based on the instantaneous current through the device. Magnetic breakers trip at multiples of their rated current. Magnetic only breakers are mostly used in industrial applications. Most modern breakers are thermal-magnetic meaning that when you are below ~10X the rated current, the breaker operates in thermal mode but somewhere between 10x and 20x the rated current, the breaker will trip in magnetic mode. The reason for the huge range is manufacturing tolerances and temperature dependencies.

One of my friends (an IEEE fellow who also worked with UL, IEC and other standard bodies) has spent considerable time studying the current profile of short circuit events captured using a high-speed oscilloscope. Instantaneous currents can easily get one into the magnetic trip range of a breaker but they don't always do so. This means they can get high enough to fry a 6 amp diode before the breaker pops. Once the diodes pop, you have an open ground leg and no more safety protection. The shorted device remains energized.

I believe you will find in Article 250 of the NEC that you cannot put any device in series with a safety ground. I don't have the NEC handy to look up the specific sub-section. I'm quite familiar with what UL is and does. They are a customer of ours. I have also worked for many manufacturers that needed UL, TUV, CE, CSA and other such certifications. There is a fair amount of lying and cheating about these and vendors sometimes get caught. And we all know that any electrical product can be a smoke machine if operated wrong enough.

As you are probably aware, circuit breakers can have thermal and magnetic trip modes. Thermal breakers take time to warm up and trip. How much time depends on the current level and ambient temperature. Thermal breakers are good at dealing with high in-rush current loads as they won't trip over the short duration of the in-rush. Their slow response makes them less prone to nuisance trips. Magnetic tripping is based on the instantaneous current through the device. Magnetic breakers trip at multiples of their rated current. Magnetic only breakers are mostly used in industrial applications. Most modern breakers are thermal-magnetic meaning that when you are below ~10X the rated current, the breaker operates in thermal mode but somewhere between 10x and 20x the rated current, the breaker will trip in magnetic mode. The reason for the huge range is manufacturing tolerances and temperature dependencies.

One of my friends (an IEEE fellow who also worked with UL, IEC and other standard bodies) has spent considerable time studying the current profile of short circuit events captured using a high-speed oscilloscope. Instantaneous currents can easily get one into the magnetic trip range of a breaker but they don't always do so. This means they can get high enough to fry a 6 amp diode before the breaker pops. Once the diodes pop, you have an open ground leg and no more safety protection. The shorted device remains energized.

I believe you will find in Article 250 of the NEC that you cannot put any device in series with a safety ground. I don't have the NEC handy to look up the specific sub-section. I'm quite familiar with what UL is and does. They are a customer of ours. I have also worked for many manufacturers that needed UL, TUV, CE, CSA and other such certifications. There is a fair amount of lying and cheating about these and vendors sometimes get caught. And we all know that any electrical product can be a smoke machine if operated wrong enough.

You're missing the obvious:Bob, the only thing I think you can take issue with . . . .

Ground loops don't exist until we do something to create them. Until then, there are simply various supply points that may or may not have slightly differing potentials relative to each other, or a given earth point.

My loops don't cause trips to GFI outlets or breakers, and they also don't inhibit the safety function of either application of that circuit protection. What they will do is prevent the creation of a ground loop between two points in a sound or AV system owing to the ground leg of the corresponding power outlets.

This is an infinitely safer practice than cutting the ground lug of power cords, or using adapters with no ground connection (which is probably how 90% of every DJ reading this deals with the issue, including yourself.) It also eliminates the need to lift the ground on balanced audio connections because it prevents the most common source of ground loops - which are those owing to differing AC supply points.

Any DJ who is plagued by venues in their area with these ground loop issues and regularly uses more than one conventional 15/20A outlet at a given site should be using a Hum-X. As we use more devices (TVs, active speakers, etc.) and start linking this outboard powered stuff back to a central rig - we are at risk of creating nuisance ground loops.

I believe you will find in Article 250 of the NEC that you cannot put any device in series with a safety ground. . .

Hopefully that won't be your response to client's when your setup sounds more like an electric razor than music and voice.

GFI is largely not used in theatrical systems because of the extensive use of shared neutrals. GFI breakers and outlets will not tolerate any imbalance in the load. Thus any GFI downstream of the distro is on the legs dropped for clients, vendors, etc. There are differing code sections for consumer, commercial, and theatrical systems.

Bob, would you care to elaborate about the "loops" you are creating? Also, I wasn't suggesting that anything you do risks tripping a GFI. I was only explaining how GFIs operate. You are correct ground loops can't exist until you do something (such as connecting two components together). Leakage currents within those components can create a loop current even if there is nothing wrong the connection that you make.

I can assure you that I don't cut ground lugs or use a HumX. I do the following:

* Operate my system off of a single circuit whenever possible

* Use a low impedance bonds between the chasses of 2-pin components

* If I must use multiple AC circuits, I galvanically isolate them using transformers or wireless connections.

* Stay away from strong magnetic sources

You may enjoy this paper on grounding. It discusses numerous hum and noise sources, the physics behind them and the safe way to deal with them.

https://indianaaes.org/wp-content/uploads/2012/09/indy-aes-2012-seminar-w-notes-v1-0.pdf

Let me know if you have any questions. The author is a very good friend of mine and if I can't answer it, I can always give him a call or ask him to call you.

BTW, here in CA, we have lots of outdoor events. Outdoor receptacles must be protected with GFIs. If I must play outdoors but get power from indoors, I add a 2' extension cord with a GFI built into it.

I can assure you that I don't cut ground lugs or use a HumX. I do the following:

* Operate my system off of a single circuit whenever possible

* Use a low impedance bonds between the chasses of 2-pin components

* If I must use multiple AC circuits, I galvanically isolate them using transformers or wireless connections.

* Stay away from strong magnetic sources

You may enjoy this paper on grounding. It discusses numerous hum and noise sources, the physics behind them and the safe way to deal with them.

https://indianaaes.org/wp-content/uploads/2012/09/indy-aes-2012-seminar-w-notes-v1-0.pdf

Let me know if you have any questions. The author is a very good friend of mine and if I can't answer it, I can always give him a call or ask him to call you.

BTW, here in CA, we have lots of outdoor events. Outdoor receptacles must be protected with GFIs. If I must play outdoors but get power from indoors, I add a 2' extension cord with a GFI built into it.

GFI is mandated outdoors everywhere in the U.S. That's a consumer and workplace safety standard applying to installations or anywhere the public is allowed unrestricted access to a electrical outlet.

That is separate from what we put in our rack to protect it from faulty or unbalanced power supplies. No, we can't build a Hum-X into the wall boxes, but we can certainly put one in our own extensjion cord - just as you choose to insert an additional GFI where you think it prudent. (If a modern installation of outdoor outlets are not showing as a GFI class it's because the GFI is at the cricuit breaker end rather than the outlet itself. This prevents accidently shock owing to defects in the outlet itself or it's branch wiring.)

The fact that a Hum-X does not impede GFI saftey is important. UL listing on the other hand, not so much.

That is separate from what we put in our rack to protect it from faulty or unbalanced power supplies. No, we can't build a Hum-X into the wall boxes, but we can certainly put one in our own extensjion cord - just as you choose to insert an additional GFI where you think it prudent. (If a modern installation of outdoor outlets are not showing as a GFI class it's because the GFI is at the cricuit breaker end rather than the outlet itself. This prevents accidently shock owing to defects in the outlet itself or it's branch wiring.)

The fact that a Hum-X does not impede GFI saftey is important. UL listing on the other hand, not so much.

GFI operation only considers the currents in the Line and Neutral conductors. The ground conductor is not part of a GFI circuit. That is why GFI still operates with a HumX. Here is a picture and schematic of the inside of a HumX. Those diodes can blow faster than a thermal fuse trips. If that happens, you lose all safety protections. The NEC does not allow for devices like this to be in the ground leg. The purpose of the 1K resistor is just to fool outlet testers into showing a properly grounded outlet.

Those diodes can blow faster than a thermal fuse trips. If that happens, you lose all safety protections.

Both of those are false statements.The purpose of the 1K resistor is just to fool outlet testers into showing a properly grounded outlet.

You haven't verifed the rating of the two diodes, don't know their material failure point, or the rise time required to physically break the connection. You have not done any testing.

There is no basis for accusing the manufacturer of deception in it's placement of the resistor. You don't know it's value and haven't fully considered it's ultimate purpose in the use of the product.

It is a perfectly suitable product available on the market and in use today. Your only gripe is that it's not UL approved. Thousands of manufacturers choose not to pay the $5,000 - $50,000 in fees required to receive UL approval.

Not sure what your fascination is with GFI but it's not really relevant to what a well designed ground loop interrupter does.

Last edited:

Bob, your ignorance on these matters is criminally dangerous. I hold a degree in electrical engineering and have worked in the EE field since the late 70s. One of my early jobs involved the design semiconductor devices and analysis of their failures. In my work with the brains behind companies such as Jensen Transformers and SurgeX I saw the studies on the real-world trip behaviors of common circuit breakers and surge suppressors. The real world is not pretty. What is the source of your expertise on these matters?

While I didn't pull apart the HumX others that have confirmed that they are 6 amp diodes. The part number is written on the device. You can't see the part number in the picture I posted but you can see the diode size relative to the receptacle's neutral slot is about the same. This would be consistent for common 6A diodes.

The first graph is a relevant specification from a typical 6A diode. It shows how many half-wave pulses the diode can handle at overload conditions. Note that in this case 250A is enough to blow the diode in a single half cycle. 250 amps is about 12 times the typical 20 amp breaker. This graph is for a typical device. In other words, some diodes will pop at lower currents.

The second graph shows the trip curve for a typical SquareD thermal-magnetic breaker. There is a grey area that reflects the manufacturing and thermal tolerances of the breaker. You can see that magnetic tripping can occur as low as 9x the rated current (180A) but as high as 22x the rated current (440A). That diode is blowing at ~12x the rated current. Maybe you would bet your life on that being safe enough but would you bet someone else's?

So you see, my opinion is validated by device specifications, real-world knowledge of the devices and expert opinions. You have offered nothing more than your personal PoV.

BTW, I am not hung up about the UL listing. However, Ebtech themselves had claimed for many years that they were working on UL approval for the HumX. They never got it. While such approval is not required, they apparently tried and failed to get it. If the device was inherently safe, approval should have been easy.

While I didn't pull apart the HumX others that have confirmed that they are 6 amp diodes. The part number is written on the device. You can't see the part number in the picture I posted but you can see the diode size relative to the receptacle's neutral slot is about the same. This would be consistent for common 6A diodes.

The first graph is a relevant specification from a typical 6A diode. It shows how many half-wave pulses the diode can handle at overload conditions. Note that in this case 250A is enough to blow the diode in a single half cycle. 250 amps is about 12 times the typical 20 amp breaker. This graph is for a typical device. In other words, some diodes will pop at lower currents.

The second graph shows the trip curve for a typical SquareD thermal-magnetic breaker. There is a grey area that reflects the manufacturing and thermal tolerances of the breaker. You can see that magnetic tripping can occur as low as 9x the rated current (180A) but as high as 22x the rated current (440A). That diode is blowing at ~12x the rated current. Maybe you would bet your life on that being safe enough but would you bet someone else's?

So you see, my opinion is validated by device specifications, real-world knowledge of the devices and expert opinions. You have offered nothing more than your personal PoV.

BTW, I am not hung up about the UL listing. However, Ebtech themselves had claimed for many years that they were working on UL approval for the HumX. They never got it. While such approval is not required, they apparently tried and failed to get it. If the device was inherently safe, approval should have been easy.

Like many engineers what you lack is common sense,

Time to put the narcissist back in the closet, along with his graphs.

The Hum-X (ebTech) is rated for just 6A (120V) That's a clear indication that it's designed to serve a single device - like a keyboard or some other line operated piece of gear that is the source of a nasty ground loop. [ you know . .the crappy gear engineered to sell for cheap. ] It's not meant to be placed at the branch outlet on a whole rig, but even then it's 12A architecture will take longer to cook than the 15A breaker in your power strip. (Real world testing - not armchair engineering.) Will it survive a lightning strike? No. (But, neither will the keyboard player.)

] It's not meant to be placed at the branch outlet on a whole rig, but even then it's 12A architecture will take longer to cook than the 15A breaker in your power strip. (Real world testing - not armchair engineering.) Will it survive a lightning strike? No. (But, neither will the keyboard player.)

Choose the correct components for the margin of safety you want. Build 35A bridge rectifiers that can withstand 600V if it makes you feel better. But let's leave the Wizard . . in Oz where he belongs.

I'm not a betting man, but if I were I'd have no doubt your gear bag has a few of these: and it ain't 'cause you're working in buildings with 100 year old electrics! I'll take the Hum-X over a 3-2 every time.

and it ain't 'cause you're working in buildings with 100 year old electrics! I'll take the Hum-X over a 3-2 every time.

The thing you don't have a hold on is common sense ( - I get it, this happens with some engineers.)I hold a degree in electrical engineering and have. . .

Time to put the narcissist back in the closet, along with his graphs.

The Hum-X (ebTech) is rated for just 6A (120V) That's a clear indication that it's designed to serve a single device - like a keyboard or some other line operated piece of gear that is the source of a nasty ground loop. [ you know . .the crappy gear engineered to sell for cheap.

Choose the correct components for the margin of safety you want. Build 35A bridge rectifiers that can withstand 600V if it makes you feel better. But let's leave the Wizard . . in Oz where he belongs.

I'm not a betting man, but if I were I'd have no doubt your gear bag has a few of these:

and it ain't 'cause you're working in buildings with 100 year old electrics! I'll take the Hum-X over a 3-2 every time.

and it ain't 'cause you're working in buildings with 100 year old electrics! I'll take the Hum-X over a 3-2 every time.What you lack sir is empathy. You have no problem risking someone's life.

Fault currents have nothing to do with how much current a device normally draws. It has to do with how much current would go down the ground if the device got damaged (say a spilled drink or knocked over speaker). You have demonstrated ZERO knowledge of real world fault currents, breaker trip characteristics and diode failure modes. However, because you haven't been bitten yet, you believe what you do must be inherently safe. I'm still waiting for you to provide any semblance of an argument that involves real facts instead of your personal observations.

Here's an analogy. Most people speed. The speed limit between LA and Vegas is 70 mph for much of the way. Many people are doing 85-100 miles per hour on this lonely straight stretch of highway without a problem. All seems fine and safe until a tire blows, some debris lands on the road or someone cuts you off. The speed isn't a problem until you try to make an evasive maneuver. At high speeds you can easily roll the vehicle and end up with a minor case of death. This sir, is how you are operating your business.

BTW, not a single cheater plug in my arsenal but I do keep a half dozen transformers in my bag and even a few wireless links.

Fault currents have nothing to do with how much current a device normally draws. It has to do with how much current would go down the ground if the device got damaged (say a spilled drink or knocked over speaker). You have demonstrated ZERO knowledge of real world fault currents, breaker trip characteristics and diode failure modes. However, because you haven't been bitten yet, you believe what you do must be inherently safe. I'm still waiting for you to provide any semblance of an argument that involves real facts instead of your personal observations.

Here's an analogy. Most people speed. The speed limit between LA and Vegas is 70 mph for much of the way. Many people are doing 85-100 miles per hour on this lonely straight stretch of highway without a problem. All seems fine and safe until a tire blows, some debris lands on the road or someone cuts you off. The speed isn't a problem until you try to make an evasive maneuver. At high speeds you can easily roll the vehicle and end up with a minor case of death. This sir, is how you are operating your business.

BTW, not a single cheater plug in my arsenal but I do keep a half dozen transformers in my bag and even a few wireless links.

Can I find this lack of empathy somewhere on your graph? . . . You don't seem to have any actual test results for that either.What you lack sir is empathy. You have no problem risking someone's life.

Calling people "killers" because they don't subscribe to your over-zealous approvals is unfortunate. I'll take a pass on Californian values (the incessant need to dictate other people's priorities.)

This is classic over-engineering - a continuous stream of "what-if's" and the urgent examples: speeding cars!

Perfectionism and engineering are a very poor mix.

Do you know why electric cars aren't selling?

- Because they're over-engineered and under-perform. They fail to resolve the transportation needs and desires of most drivers.

- Because it's the fastest way to cut through all the red tape. (sociopolitical over-engineering)

I stand by my own time proven and shop tested results. It works really, really well.

For a noisy device giving presenting with obvious ground loop issues (meaning if you lift the ground it goes away) then give the Hum-X a try so you can enjoy better sound while also maintaining a safety ground. Only use the Hum-X for individual devices at or below 5 amps (600W) 120V and place it last on the end of the line closest to the problem device. At loads greater than 600W a Hum-X may permanent;y lose it's ability to stop the ground loop. It will NOT (as has been suggested) "blow up." If you're dealing with a venue that has very poor quality electrics, place a surge protector/power strip ahead of the hum-X to preserve it's ground loop stopping feature, and obviously to proect your device.

My own loops are built to be more robust than a Hum-X but the fundamental quality of result and time saved is great. Never going back to doing it any other way.

Last edited:

Bob, I truly question why you bother to participate on chat forums. There is clearly nothing this world can teach you. You regularly demonstrate your disdain for everyone here. You treat any advice offered that differs from your own methods as an attack on your person. I can't begin to know why your ego is so fragile.

You and I disagree on the safety of a hum elimination method. The solution you like has been on the market for over 20 years without competition despite it being neither patented nor costly to implement. Every manufacturer of commercial, professional, broadcast, or consumer audio gear could easily implement this solution into their gear if they wanted to. Yet none have. You should be asking yourself why that is. It might just be possible that Yamaha, QSC, Meyer, Digico, A&H, EV, D&B, JBL, Powersoft, Lab Gruppen, and all those other companies actually understand the circuit and its risks more than you.

I have provided the science to back up why people avoid this solution. You have provided character attacks to back up your views. If you want to continue attacking people, do it through personal messages. There is no reason to demonstrate to the entire board how much of a contemptible arse you can be.

I'm going to do everyone the favor of locking this thread. I suggest you let this die. If not, I am happy to give you a much needed vacation.

You and I disagree on the safety of a hum elimination method. The solution you like has been on the market for over 20 years without competition despite it being neither patented nor costly to implement. Every manufacturer of commercial, professional, broadcast, or consumer audio gear could easily implement this solution into their gear if they wanted to. Yet none have. You should be asking yourself why that is. It might just be possible that Yamaha, QSC, Meyer, Digico, A&H, EV, D&B, JBL, Powersoft, Lab Gruppen, and all those other companies actually understand the circuit and its risks more than you.

I have provided the science to back up why people avoid this solution. You have provided character attacks to back up your views. If you want to continue attacking people, do it through personal messages. There is no reason to demonstrate to the entire board how much of a contemptible arse you can be.

I'm going to do everyone the favor of locking this thread. I suggest you let this die. If not, I am happy to give you a much needed vacation.

- Status

- Not open for further replies.